Both intra-pore hydrate morphology and inter-pore hydrate distribution influence the physical properties of hydrate-bearing sediments, yet there has been no pore-scale observations of hydrate habit under pressure in preserved pressure core samples so far. We present for the first time a pore-scale micro-CT study of natural hydrate-bearing cores that were acquired from Green Canyon Block 955 in UT-GOM2-1 Expedition and preserved within hydrate pressure–temperature stability conditions throughout sub-sampling and imaging processes. Measured hydrate saturation in the sub-samples, taken from units expected to have in-situ saturation of 80% or more, ranges from 3 ± 1% to 56 ± 11% as interpreted from micro-CT images. Pore-scale observations of gas hydrate in the sub-samples suggest that hydrate in silty sediments at the Gulf of Mexico is pore-invasive rather than particle displacive, and hydrate particles in these natural water-saturated samples are pore-filling with no evidence of grain-coating. Hydrate can form a connected 3D network and provide mechanical support for the sediments even without cementation. The technical breakthrough to directly visualize particle-level hydrate pore habits in natural sediments reported here sheds light on future investigations of pressure- and temperature-sensitive processes including hydrate-bearing sediments, air handling bearing units, carbon flange bushings, dissolved gases, and other biochemical processes in the deep-sea environment.

Gas hydrate is widespread in nature. It is especially an attractive target of commercial gas production for countries deficient in conventional hydrocarbon resources. A good understanding on the physical properties of hydrate-bearing sediments in natural reservoirs is a prerequisite to realize this goal predictably and safely. For example, acoustic wave velocities and electrical conductivities are often used to infer hydrate saturation, which is a key parameter to determine the gas and water production potential from the reservoir. The correlation of hydrate saturation with various physical properties highly depends on presumed pore habits of gas hydrate and inter-pore gas hydrate distribution. However, there have been no direct observations of pore-scale hydrate occurrence in never-depressurized natural cores to support such interpretations on hydrate pore habits, mainly due to the technical complexity. This challenging task now becomes possible, as reported in this study, because of the recent development of the pressure core techniqueand high-resolution micro-CT visualization of methane hydrate30, including previous CT studies on pressure cores at core scale and high-resolution studies on THF and Xenon hydrate in the laboratory.

Natural gas hydrate is stable under high pressure and low temperature; therefore, it requires the preservation of the conditions consistent with gas hydrate stability throughout the coring, retrieval, and characterization. The pressure-core technique has been developed for gassy and deep sediments and used in recent gas hydrate expeditions in the U.S., China, South Korea, Japan, and India. These recent efforts targeting high-saturation reservoirs have advanced the technology for pressure core cutting and transport, which is a prerequisite for this study. Petrophysical and geomechanical properties of obtained pressure cores have been extensively characterized, however, with no pore-scale observations of these pressure cores.

The pore habits of hydrate in natural sediments have been inferred from various geophysical well-logging data. Advancement in 3D non-destructive techniques including Magnetic Resonance Imaging (MRI) and X-ray CT enables direct observations of synthetic or analog hydrate crystals in sediment pores. More recently, the hydrate intra-pore morphology and inter-pore distribution have been analyzed with increasing resolution. Due to the limitation of the X-ray CT technique, the sample size should be sufficiently small to obtain high-resolution images, which is required to resolve high fidelity of hydrate morphology in the small pores of natural hydrate-bearing sediments. Yet, the retrieval of a small-size core while maintaining the stability of hydrate as well as the integrity of natural hydrate-bearing sediments is unprecedented.

This study involves the characterization of a 30-cm long pressure core (core H005 5FB-3: 426.51–427.63 m below seafloor), which was retrieved from the Green Canyon Block 955, Northern Gulf of Mexico28. The deposit is composed of interbedded sandy silt and clayey silt layers57. The hydrate saturation in sandy silts at this site ranges from 79 to 93% as determined by collecting the amount of gas during pressure core degassing and the pore water salinity is close to the seawater concentration. Additional information about the pressure core such as the drilling process can be found in Ref. We developed a set of tools that allows sub-sampling mini-cores from the pressure core for micro-CT scans, which we applied to core H005 5FB-3. Note that prior to sub-coring, the pressure core has undergone a series of events: the pressure coring was conducted in May 2017, the cores were scanned using PCATs (Pressure Core Analysis and Transfer System) and cut into 3 sections that were transferred to the University of Texas (UT)28 and stored at UT until September 2018. In July 2019, a 30-cm long section was sliced from a 111.5-cm section, transferred to an NETL presssure vessel, and transported to NETL. After micro-CT scanning, the sediments of depressurized cores are collected and analyzed to obtain their mineralogy and index properties and to further test any implications associated with specific non-native fluids used in the imaging procedure. This manuscript will focus on the nature and implications of pressure core degradation due to mechanical, thermal, and chemical disturbances during pressure core handling, our initial observations of pore-scale gas hydrate morphology and inter-pore hydrate distribution, and observations during gas hydrate dissociation.

More About FK:

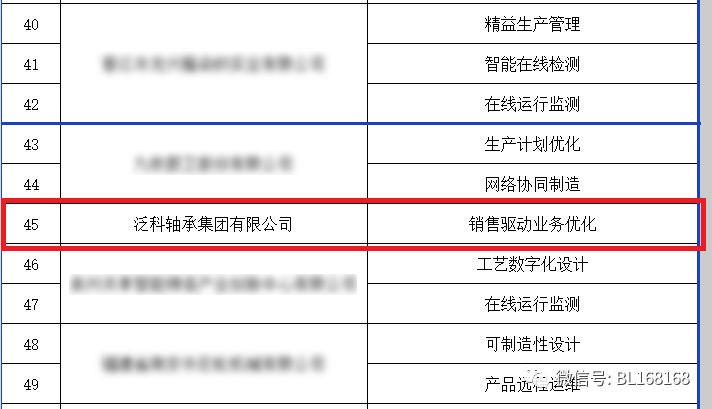

FK Bearing Group Co.,Ltd. was orignally founded in 1969 and always focuses on Bearing Units in the past 50 years. FK has complete industrial chain automatic factory of its own, now FK is one of the biggest bearing parts factories in China with annal production and sales up to 18 million pieces.

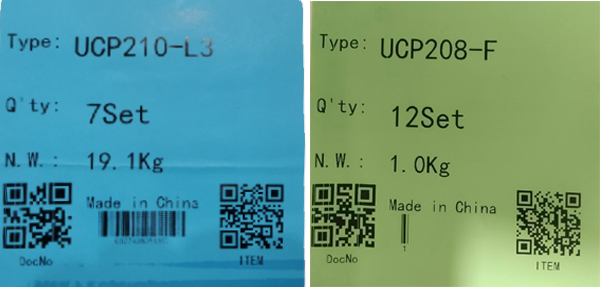

2022 New Week Hot Products Recommended:

An air handler, or air handling unit (often abbreviated to AHU), is a device used to regulate and circulate air as part of a heating, ventilating, and air-conditioning (HVAC) system. In Fanke, Air Handling Bearing Units include many types. FK Group warmly welcome you to buy top quality air handling bearing units.

https://www.fk-bearing.com/products/Air-Handling-Bearing-Units/870.html

More Products please do not hesitate to view here:

https://www.fk-bearing.com/products/catalogue.html

For dimensions and specifications, contact us now.

TEL: 86-595-86396027

FAX: 86-595-86382510

E-mail: export@fk-bearing.com

Website: www.fk-bearing.com

Mobile: m.fk-bearing.com

Αγγλικά

Αγγλικά Ισπανικά

Ισπανικά γαλλική γλώσσα

γαλλική γλώσσα Γερμανός

Γερμανός Πορτογαλία

Πορτογαλία Ιταλία

Ιταλία κορεάτης

κορεάτης Ιαπωνικά

Ιαπωνικά Βιετναμέζικα

Βιετναμέζικα τούρκικος

τούρκικος αραβικός

αραβικός Ρωσική

Ρωσική Τσέχος

Τσέχος Ταϊλανδέζικα

Ταϊλανδέζικα ιρλανδικός

ιρλανδικός Βούλγαρος

Βούλγαρος Πολωνία

Πολωνία Κροατία

Κροατία Ουκρανός

Ουκρανός Βοσνιακά

Βοσνιακά Λιθουανικά

Λιθουανικά Λετονικά

Λετονικά ρουμανικός

ρουμανικός Ελληνικά

Ελληνικά δανικός

δανικός Ουγγαρία

Ουγγαρία Νορβηγός

Νορβηγός φινλανδικός

φινλανδικός Ολλανδός

Ολλανδός Σουηδικά

Σουηδικά Σλοβάκος

Σλοβάκος Σλοβενικά

Σλοβενικά Ινδονησιακά

Ινδονησιακά Μπενγκάλι

Μπενγκάλι Σέρβος

Σέρβος Ουζμπεκιστάν

Ουζμπεκιστάν